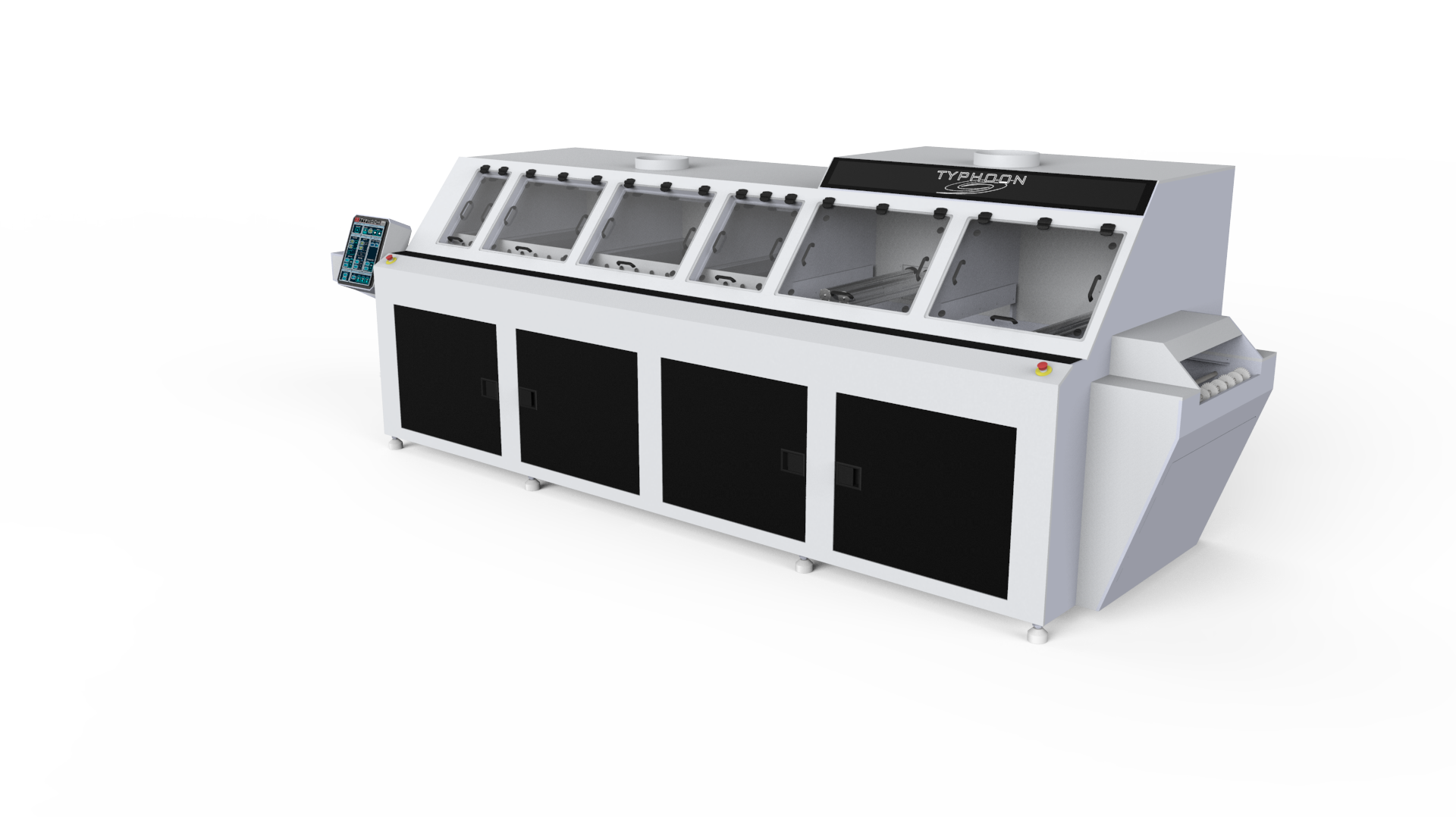

Our T-15 was the pilot model Typhoon for all other cleaners (T-9,T-12, and T-20) and we continue to use it as our template to expand the range of solutions we offer. When we began building the T-15 we sought out to differentiate ourselves from the existing market. We accomplished this by offering our STANDARD cleaner with parts & components necessary for efficiently and effectively cleaning your products.

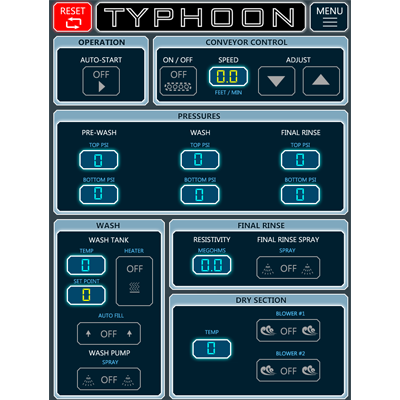

Not only does it effectively clean your product, we also made it extremely simple for your maintenance staff to maintain The Typhoon. All plumbing is easily accessible so wash pressures can be adjusted and monitored in the same location. Our drain valves are easily accessible in the front doors; our wash tanks are covered by water-tight lids that are easily removed. Each of the six sections within the cleaning process are visible, so you are able to see the transition of your product from dirty assembly to ready to ship within 15 feet.

In the past we saw too many issues with the traditional screw-in heaters which melt to the plastic/threads and make them incredibly difficult to maintenance. We decided to use a drop in immersion heater, where the heating portion is offset from machine providing a physical barrier between the machine and the heating element. A secondary safety measure within the heaters is an over-temp setting, in which once the heater reaches a specific temperature the heater immediately shuts off to prevent any damage to the machine.

A majority of our replacement parts are readily available at vendors placed throughout major US cities. We also sell all replacement parts ourselves and can have them shipped from our facility to yours.